NX3A1E2-M NEXUS PRESSPro II Stamping Press Automation

Description

NX3A1E2-M NEXUS Networked I/O PRESSPro II Stamping Press Automation

AMCI makes it easy and affordable to upgrade your PLC-based stamping press system with sophisticated controls that are usually associated with large, expensive machinery. The original NX3A1E1-M, in successful service since 2007, is now available in the E2 series with a new two port network module and a new part number NX3A1E2-M.

The NEXUS PRESSPro II incorporates “hard to find” stamping press automation functions, normally purchased individually, into a single product that saves time & money. These functions include:

A) Brake Monitor

AMCI’s PRESSPro II uses a resolver-based brake monitor to measure braking performance and alert operators if preset stop time limits are exceeded. The monitor’s advanced warning enables stamping press operators to schedule maintenance at the factory’s convenience, avoiding an unplanned shutdown.

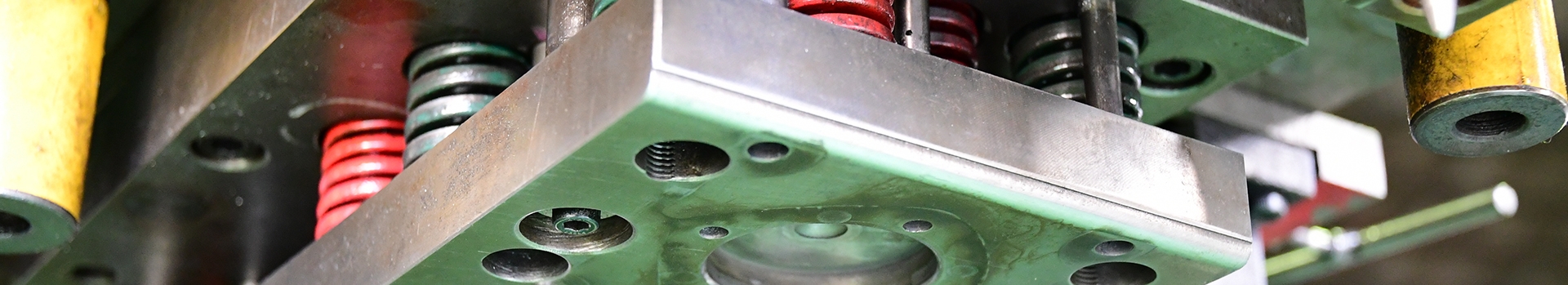

B) Die Protection

Operating errors such as misfeed, short feed, long feed, buckle detects & part eject can ruin a die and disable your press. Prevent costly repairs and/or damage to your dies by protecting against unexpected events using the PRESSPro II die monitoring function.

C) Tonnage Monitor

Extend the life of your stamping press and dies using the PRESSPro II tonnage monitor to optimize ram force and prevent excessive hard hitting. Capacity, high, low, and data window set points can be configured; if any of the set points are crossed an error will be reported to stop the press.

D) Programmable Limit Switch (PLS)

The PRESSPro II incorporates a resolver-based high speed PLS controller that synchronizes external equipment with machine timing such as; feed, part transfer, conveyor control, etc. A heavy duty absolute resolver reports accurate control position of the stamping press stroke, which eliminates time consuming adjustments associated with rotary cam

Available Versions

NX3A1E2-M: Stamping press automation controller with network connection

Consult the factory for availability

Contact SalesNEXUS PRESSPro II Stamping Press Automation

AMCI makes it easy and affordable to upgrade your PLC-based stamping press system with sophisticated controls that are usually associated with large, expensive machinery. The NEXUS PRESSPro II incorporates “hard to find” stamping press automation functions, normally purchased individually, into a single product that saves time & money. These functions include:

AMCI NEXUS PRESSPro II

|

|

|

||

|

limit switches replace antiquated rotary cam switches that are inflexible, subject to wear, and slow down your production changes. |

NX3A1E2-M Features

- Brake monitor

- Die Monitor/Protection

- Tonnage Monitor

- High speed Programmable Limit Switch

- Dual-port networking offers offers DLR for EtherNet/IP & MRP for Profinet

PLC-Based Specialty I/O Solutions

Functionally, the AMCI NEXUS controllers and interfaces deliver the same level of PLC integration as their plug-in module counterparts, but with much more flexibility from a systems standpoint. Rather than limit these versatile products to one PLC brand or specific backplane, all units are Din-rail mountable and equipped with a network interface that allows connection to various controllers. AMCI NEXUS specialty I/O integrate with ANY network enabled PLC using Ethernet I/P, Modbus TCP/IP, Profinet, Profibus, ControlNet, or DeviceNet.

The flexibility of a NEXUS controls solution saves time and money, letting customers choose whatever PLC best meets their needs, or change PLCs without having to re-specify and repurchase plug-in modules. And because the NEXUS integrates via network communication, PLC platforms no longer restrict compatibility and integration.

Compatible Networks

NEXUS is compatible with any networked PLC that supports these networks

The Best PLC Integration Available

AMCI products are uniquely designed to provide the best PLC integration available. Unlike other products that require a separate software package for configuration or operation, AMCI's PLC-based products are programmed using your PLC's software - nothing new to buy or learn!

Our expertise with the leading PLC manufacturers (e.g. Allen-Bradley Schneider, GE, etc) is unmatched when it comes to high performance Specialty I/O, Position Sensing, and Motion Control technology.

Program Using Your Existing Software

AMCI's products program using your PLC's native software - nothing new to learn or buy!

Specifications

Product Specifications

| AMCI Module | NX3A1E2-M |

|---|---|

| Network Availability | EtherNet IP, Modbus TCP/IP, & Profinet w/ Embedded Switch |

| Programmable Limit Switch | Sensor feedback: resolver Number of resolver channels: 1 Number of high speed outputs: 16 Motion detect output : 1 Fault output: 1 Output update time: 50us |

| Brake monitor | Number of brake monitor inputs: 1 Current supplied: 15mA @ 24Vdc required (Input Relay Dependent) |

| Die Protection | Die monitoring inputs: 16 discrete Input scan time: 500us Power requirement: each input sources 0.5mA of current Five die protection types: • Normally true • Normally false • Cyclical • Constant • Quick |

| Tonnage Monitor | Number of strain gauge inputs: 4 Reference voltage: 5Vdc Current supplied: 100mA max Signature Data: 256 bytes of strain gauge data stored on every cycle of the press |

| Diagnostics | Signature analysis: outputs tonnage data directly to controller/display for visually mapping force profiles |

| Power Supply | Range: 18 to 30Vdc. Optimum: 670 mA @ 24Vdc (Does not include load on Strain Gauges Dedicated power supply (only for press control devices) recommended |

| Environmental | Operating Temperature: 0 to 60° C Optimum: 670 mA @ 24Vdc (Does not include load on Strain Gauges Dedicated power supply (only for press control devices) recommended |

| Transducer compatibility | H25 / HT-6 / HT-20 / HT-400 HT-20-(X) / R11X-J10/7 |

| Cable Requirements | CTL-X |

| Input connector | Resolver Input Connector (1 per unit) AMCI Part # = MS-8 Phoenix Contact Part # = MSTB2.5/8-ST-5.08 One connector is included with the unit  |

Product Specifications

Number of resolver channels: 1

Number of high speed outputs: 16

Motion detect output : 1

Fault output: 1

Output update time: 50us

Current supplied: 15mA @ 24Vdc required (Input Relay Dependent)

Input scan time: 500us

Power requirement: each input sources 0.5mA of current

Five die protection types:

• Normally true

• Normally false

• Cyclical

• Constant

• Quick

Reference voltage: 5Vdc

Current supplied: 100mA max

Signature Data: 256 bytes of strain gauge data stored on every cycle of the press

Optimum: 670 mA @ 24Vdc (Does not include load on Strain Gauges

Dedicated power supply (only for press control devices) recommended

Optimum: 670 mA @ 24Vdc (Does not include load on Strain Gauges

Dedicated power supply (only for press control devices) recommended

Connector

(1 per unit)

AMCI Part # = MS-8

Phoenix Contact Part # = MSTB2.5/8-ST-5.08

One connector is included with the unit

AMCI makes buying PLC-based automation easy...our sales group will help you:

- Select the right product for your application

- Pay by credit card using your Visa, Mastercard, Discover, or American Express

- Coordinate alternative payment methods (P.O., wire transfers, etc.)

- Locate a distributor convenient to your region of the country

Contact AMCI Sales today:

860-585-1254

Ordering Information

AMCI's sales team takes the hassle out of placing your order. We'll advise on product selection, alternatives, lead times, and present you with point of purchase options. Call (860) 585-1254 or email AMCI sales today!

Resources

PRESSPRo II Brochure

AMCI makes it easy and affordable to upgrade your PLC-based stamping press system with sophisti...

Download PDF