AMCI Stepper Motors Improving Palletizing Efficiency

providing a cost-effective, reliable solution

providing a cost-effective, reliable solution

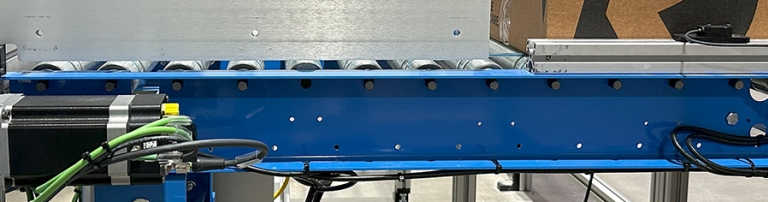

READY Robotics designed a modular solution for customers who need an industrial palletizer built to fit their exact needs, without the long deployment times of a traditional custom solution. READY Cells: Palletizing features configurable infeed conveyors and low-code or no-code programming, making it simple for new and experienced programmers.

READY required a solution that could move multiple axes with safety and precision, while seamlessly integrating with Allen Bradley PLCs over Ethernet IP. One axis would have a motor pushing an arm down the conveyor and a load along with it. This requires a significant amount of torque and precision, but most importantly, some level of safety to protect users and the machine. A second axis would control the lever arm, raising and lowering to control the direction the load’s travels. The last axis controls the orientation of the gripper mechanism.

AMCI’s SMD series of integrated stepper motors, featuring dual-port ethernet for Ethernet IP communication, STO, and absolute encoders, perfectly met READY’s requirements. As a Technology Partner with Rockwell Automation, AMCI offers streamlined axis programming through custom EDS files, labeled data tags, and add-on instructions (AOIs). The compact SMD23E2 proved ideal for the lever arm and gripper orientation axes, providing a cost-effective solution. The SMD34E2 delivers increased torque and all essential features for optimal performance. Absolute multi-turn encoders in the SMD23E2 and SMD34E2 models provide precise position feedback for each axis on the READY Cells: Palletizer, alongside integrated Safe Torque Off (STO) for system reliability.

AMCI’s SMD series of integrated stepper motors, featuring dual-port ethernet for Ethernet IP communication, STO, and absolute encoders, perfectly met READY’s requirements. As a Technology Partner with Rockwell Automation, AMCI offers streamlined axis programming through custom EDS files, labeled data tags, and add-on instructions (AOIs). The compact SMD23E2 proved ideal for the lever arm and gripper orientation axes, providing a cost-effective solution. The SMD34E2 delivers increased torque and all essential features for optimal performance. Absolute multi-turn encoders in the SMD23E2 and SMD34E2 models provide precise position feedback for each axis on the READY Cells: Palletizer, alongside integrated Safe Torque Off (STO) for system reliability.

see it in action!