Application Examples

AMCI’s specialized control solutions are used in applications ranging from sophisticated motion control systems for the pharmaceutical industry to extreme duty position feedback solutions for military assault vehicles.

Specialty I/O

Precise Valve Control

Pulse Width Modulation (PWM)

A customer recently inquired about a custom solution to fill their need for precise valve control. The customer was looking for a high number of nodes, and required a low cost solution. AMCI developed a new Pulse Width Modulation (PWM) output module to fill this need. AMCI's 4402 PWM module provides up to 1.5A at 24Vdc output to control DC solenoid valves. AMCI selected Point I/O as the hardware base to reduce cabinet space, meet the high node count and reduce cost. The user configurable frequency and duty cycle supports multiple valve types and offers seamless integration into the PLC.

Application Summary

Requirements: valve control, high number of nodes, low cost

Solution: 4402 PWM module for Point I/O

Rail Track Grinders

Heavy-Duty Position Feedback

Harsco Track Technologies is a chief global supplier of railway track maintenance equipment and services. The company provides track maintenance services to major railroads, short lines, and transit systems, and is a leading source for over 140 types and models of work equipment used in the maintenance, renewal, and new construction of railway track.

Read the full case study...

Application Summary

Requirements: withstand extreme conditions and wide range of temperatures, analog output, bullet-proof reliability

Solution: DuraCoder Encoders

Upgrade from Proximity Switches

Heavy-Duty Position Feedback

The country's largest fluorescent tube lighting manufacturer recently upgraded their old proximity switches with AMCI's resolver-based encoders. The upgrade greatly reduced maintenance costs & feedback reliability by eliminating issues with glass debris and controls calibration due to heavy vibration. AMCI's encoder products provide IP67 protection, withstanding heavy shock & vibration as well as ingress from contaminants.

Application Summary

Requirements: increase feedback reliability, reduce costs, withstand glass debris and heavy vibration

Solution: DuraCoder Encoders

Waterfall Swing

Heavy-Duty Position Feedback

A pair of AMCI encoders are a part of an interactive art piece installed at the OK Center for Contemporary Art in Linz, Austria. The Waterfall Swing has two swings that pass through a computer controlled wall of water that opens for riders to pass through without getting wet. The encoders send the swing seat position (angle & speed) to the computer that controls the water printer. www.waterfallswing.com

Application Summary

Requirements: position feedback, water ingress protection

Solution: DuraCoder Encoders

Aerial Fire Trucks

Heavy-Duty Position Feedback

AMCI encoders are mounted on ladder base swivels (swivels allow for rotation of the aerial ladder while acting as a pass-through for water and continuous hydraulic and electrical circuits) to monitor the position of the fire truck's aerial ladder, reducing risk of injury and damage to equipment. Prior to using AMCI encoders, proximity switches were being used to detect whether the ladder was within or beyond certain degrees of rotation using physical flags. The old method couldn’t monitor the position of the ladder within the 0 to 180 degree range of allowable travel. Using AMCI encoders provides the position feedback they need, telling them where the ladder is within the 0-360 degree revolution without any guesswork. Read the full case study...

Application Summary

Requirements: reliable position feedback, analog output/reduce programming, integral cable, IP67 rating

Solution: DuraCoder Encoders

Theme Park Rides

Heavy-Duty Position Feedback

AMCI encoders are used to measure the speed and velocity of roller coasters including those in the biggest, most popular theme parks.

Application Summary

Requirements: withstand heavy vibration, reliable position feedback

Solution: DuraCoder Encoders

Motion Control

Updated Flow Wrapper

High-Speed, Low-Torque Stepper Control

A Confections manufacturer updated their flow wrapper from a mechanical system to a modern, automated system with PLC-based control using AMCI's SD17060E stepper drive + controller with Ethernet/IP and AMCI's SM34 stepper motor with encoder. This product combination managed the machine’s high speed and torque requirements, and simplified the coordinated motion control between the machine’s feed speed and product sealing. The drive’s electronic gearing feature mathematically links the position of a slave axis (product sealing) to the position of a master axis (feed speed). Plus, the drive’s Ethernet/IP connection simplified integration with the existing PLC.

Application Summary

Requirements: automated motion control, high speed, low torque, coordinated motion control, electronic gearing, EtherNet/IP

Solution: SD17060E2 & SM34 stepper motor with integrated encoder

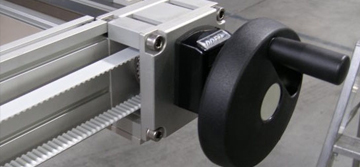

Set-Up Axes: No More Manual Adjustments

Low-Cost 3-in-1 Stepper Motion Control

AMCI's SMD23E have replaced the manual adjustment previously required for machine set up axis. The simple programming and low cost has allowed integrators and OEM's to add auto-setup features to reduce change over time, and increase the repeatability of system between change overs.

Application Summary

Requirements: automate set up axis, reduce change over time, low cost

Solution: SMD23E

Bottling Filling Line

Integrated Stepper Drive/Control with EtherNet/IP

A national art supply company updated their bottle filling line with a multi-axis motion controller/drive from AMCI. The upgrade replaced inefficient pneumatic actuators eliminating over/underfills of paint bottles. Set up and changeover time was reduced from 20 minutes to 20 seconds improving productivity and reducing waste. AMCI offers several motion products on Ethernet/IP. We have the right one for your application.

Application Summary

Requirements: increase efficiency, reduce changeover time, reduce waste, network interface

Solution: SD17060E2

Crayon Production Line

Integrated Stepper Drive/Control with EtherNet/IP

The world's largest crayon manufacturer uses AMCI's motion control products on their production lines to effectively reduce waste and cost of materials. AMCI's EtherNet/IP Stepper Drives (SD17060E) have contributed to increased productivity in the process of sorting & dispensing crayons into their respective product packaging. AMCI's multi-axis EtherNet/IP integrated stepper controller/drives (ANG1(E)) are used to control the pumping system that dispenses a precise quantity of paint, decreasing waste and saving money.

Application Summary

Requirements: increase production efficiency, decrease costs, multi-axis, EtherNet/IP

Solution: SD17060E2 & ANG1E

Automatic Depalletizer

Low Cost 3-in-1 Stepper Motion Control

GR-X Manufacturing specializes in container handling equipment, and uses AMCI’s SMD23E2 on their Automatic Depalletizers to control the push of the bottles. Using AMCI’s integrated stepper motor allows them to push plastic bottles of all sorts with smooth, reliable, and continuous operation; and prevents the bottles from tipping over, which was a problem with pneumatics. Plus, the motors' dual port networking Ethernet connection simplifies integration with the end users' existing PLC.

Application Summary

Requirements: automated motion control, high speed, low torque, smooth, reliable, and continuous operation, EtherNet/IP

Solution: SMD23E2 with EtherNet/IP