What is a Resolver?

When discussing RESOLVERS, people often interchange terms such as: encoders, rotary position sensors, motion feedback sensors, and transducer sensors. On occasion, synchros (cousin to the resolver) are also mentioned when explaining devices of this nature. Regardless of the names people choose to describe resolvers, their role in the world of automation remains unparalleled.

Referenced as an analog sensor that is absolute over a single turn, the resolver was originally developed for military applications and has benefited from more than 50 years of continuous use and development. It was not long before numerous industrial segments recognized the benefits of this rotary position sensor, engineered to withstand the punishment of a military application. Product packaging plants and stamping press lines are perfect examples of where you might find resolver based systems at work. In typical applications, the resolver sensor feeds rotary position data to a decoder stationed in a Programmable Logic Controller (PLC) that interprets this information and executes commands based on the machines' position.

Recent advances in technology have enabled the integration of a resolver and on-board electronics in one housing as an alternative to other types of encoders. Referred to as DuraCoders, these motion sensing devices are available with the following output types; Absolute Parallel, Incremental Digital, Analog Current, Analog Voltage, and DeviceNet. The Absolute Parallel and Incremental Digital versions can also be ordered with a field programmable option. Using simple onboard switches, technicians and engineers can easily select the unique resolution required by the application, thereby reducing the number of units that must be stocked.

Through the evolution of machine development, builders and system integrators alike, agree that the ‘resolver’ transducer is unsurpassed in its ability to reliably supply rotary position data in the harshest industrial environments.

RESOLVER CONTROL TRANSMITTER

|

Figure 1.1 Typical Brushless Resolver Cross Section

|

A resolver is a rotary transformer where the magnitude of the energy through the resolver windings varies sinusoidally as the shaft rotates. A resolver control transmitter has one primary winding, the Reference Winding, and two secondary windings, the SIN and COS Windings. (See figure 1.1, Resolver Cross Section). The Reference Winding is located in the rotor of the resolver, the SIN and COS Windings in the stator. The SIN and COS Windings are mechanically displaced 90 degrees from each other. In a brushless resolver, energy is supplied to the Reference Winding (rotor) through a rotary transformer. This eliminates brushes and slip rings in the resolver and the reliability problems associated with them.

|

|

|

Figure 1.2 Brushless Resolver Control

Transmitter Schematic |

In general, in a control transmitter, the Reference Winding is excited by an AC voltage called the Reference Voltage (Vr). (See figure 1.2, Resolver Schematic). The induced voltages in the SIN and COS Windings are equal to the value of the Reference Voltage multiplied by the SIN or COS of the angle of the input shaft from a fixed zero point. Thus, the resolver provides two voltages whose ratio represents the absolute position of the input shaft. (SIN θ / COS θ = TAN θ, where θ = shaft angle.) Because the ratio of the SIN and COS voltages is considered, any changes in the resolvers’ characteristics, such as those caused by aging or a change in temperature, are ignored. An additional advantage of this SIN / COS ratio is that the shaft angle is absolute. Even if the shaft is rotated with power removed, the resolver will report its new position value when power is restored.

RESOLVER CONTROL TRANSFORMER

|

Figure 1.3 Brushless Resolver Control Transformer Schematic

|

A resolver control transformer has two input stator windings, the SIN and COS windings and one rotor output winding. (See figure 1.3) The rotor output is proportional to the sine of the angular difference between the electrical input angle of the inputs and the mechanical angular position of its shaft...in other words, the voltage induced into the rotor is proportional to Sin(Φ–θ), where θ is measured from some reference shaft position called zero.

| Figure 1.4 shows what might be called the "classic" resolver mechanical follow-up servomechanism. The command angle is established by the shaft position of the control transmitter. When the servomotor has reached the commanded position, θ1=θ2 the control transformers output is zero and the motor stops. Although the above description is oversimplified, it is useful in describing a control transformer. |

|

|

|

Figure 1.4 Typical Electromechanical Follow-up Servo

|

| Both control transmitters and control transformers are unidirectional devices i.e. Control transmitters manufacturers specifications are only valid when the electrical input is the rotor, and control transformers specifications are only valid when the electrical inputs are the stator. Although both can be used "backwards", performance cannot be guaranteed. |

What does it all mean (to you)?

When an encoder application exists in a hot, humid, dusty, oily, or mechanically demanding environment, the resolver-based system is the preferred choice. Ultra reliability, coupled with proven performance support the bulletproof reputation this rotary position sensing device has earned.

Resolvers Brochure

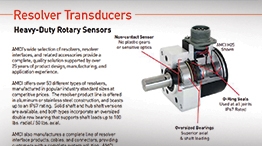

AMCI’s wide selection of resolvers, resolver interfaces, and related accessories provide a comp...

PDF DownloadResolvers Video

AMCI’s wide selection of resolver transducers, resolver interfaces for PLC based systems, and r...

Watch Now