Stepper vs Servo

This tutorial will help you understand the differences between stepper and servo motors, and how to select the best motor for your application. We will cover motor basics including construction, current, functions and features, questions to ask when selecting a motor, application examples, key terminology, and more. We also provide additional resources for more information.

Motor Basics: How a Stepper Motor Works

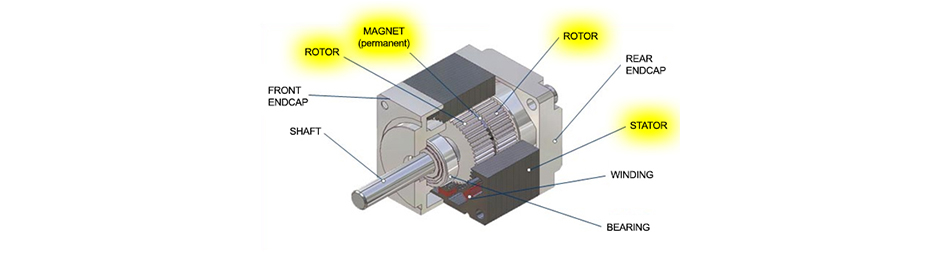

Stepper Motor Construction

Most industrial stepper motors are hybrid stepper motors that consist of a permanent magnet rotor and a wound electromagnetic stator.

Stepper Motor CURRENT

DC current is used to energize the magnetic coils of the stepper motor.

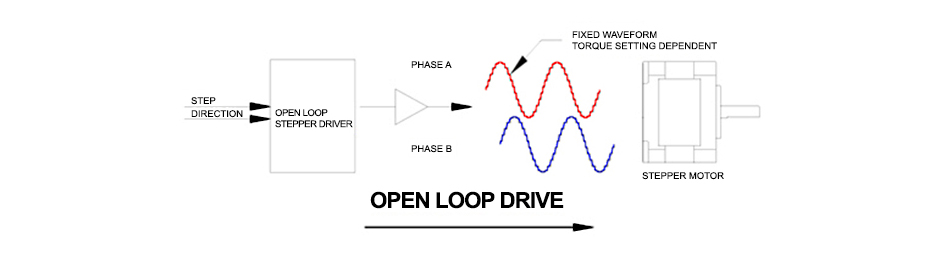

The current supplied from the drive creates a magnetic field that is used rotate the shaft of the motor. Below is the a basic representation of how this process works.

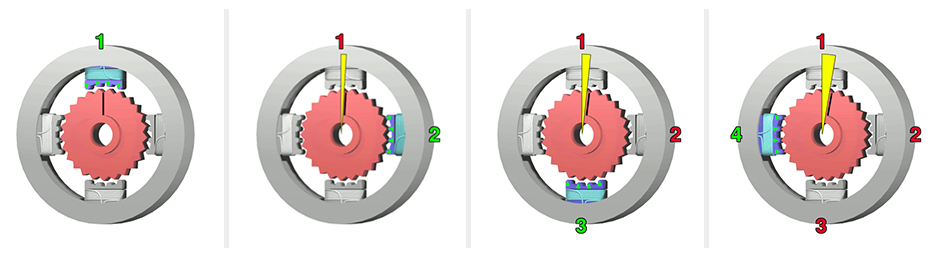

1. The upper electromagnet is activated and the teeth of the central cog line up accordingly.

2. The upper electromagnet is deactivated and the right one turned on. The closest cog teeth then jump to line up with this. This causes a step (e.g. 1.8° turn).

3. The right electromagnet is deactivated and the lower one is turned on. The cog teeth then jump to line up with the bottom electromagnet. This causes another step.

4. The bottom electromagnet is deactivated and the left-most one turned on. The cog teeth then jump to line up with this. This causes another step. On a motor which has a step angle of 1.8°, 200 steps are required for a full rotation.

Other things to know

1. Microstepping increases the number of steps/turn.

2. Increasing the current increases motor torque.

3. The higher the step frequency the higher the motor speed.

4. As motor speed increases Back EMF can reduce motor torque.

5. No position feedback required, however it is optional.

Stepper basics summary

DC current generates a magnetic field. It is an open loop, constant current system. Current is maintained while motor is at rest.

![]() Advantages

Advantages

• Simple design/control

• No feedback required

• Excellent low speed torque

• Excellent low speed smoothness

• Lower overall system cost

![]() Disadvantages

Disadvantages

• Torque decreases as speed increases

• Constant current regardless of requirements

• Cannot react to changes is load

fun stepper fact

In 1920, the actual application of stepper motors began, so called VR (Variable Reluctance) type stepper motors, used by the British Navy as positioning control and remote control.

Motor Basics: How a SERVO Motor Works

SERVO Motor Construction

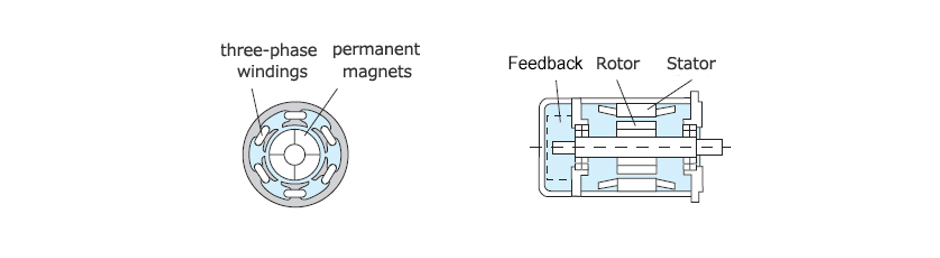

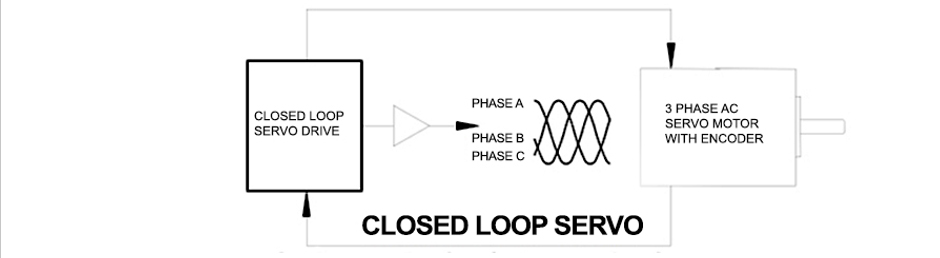

An AC servo consists of a three phase stator and a permanent magnet rotor. In addition motor feedback such as a resolver or encoder is needed for proper current control.

Servo Motor CURRENT

3 phase AC current is used to energize the magnetic coils of the servo motor.

As the current in the stator changes, the magnetic field of the three phases change; causing the permanent magnets of the rotor to align with the respective phase.

Other things to know

1.Increasing the current increases motor torque.

2.The higher the current frequency, the faster the motor will rotate.

3.Servos monitor and regulate the motor current for more precise torque control.

4.Motor feedback is required for proper current control.

Servo basics summary

Three phase AC current generates a magnetic field. It is a closed loop system that continuously monitors position relative to commanded position and adjusts current accordingly. Motor brake required for zero speed holding torque.

![]() Advantages

Advantages

• Closed loop control

• Higher torque at higher speed

• Lower motor heating

• Better choice for variable load systems

![]() Disadvantages

Disadvantages

• More complex control – tuning required

• Position feedback required

• Higher overall system cost

fun servo fact

A camera’s auto focus uses a precise servo motor built into the camera that corrects the position of the lens to sharpen out-of-focus images.

stepper or servo?: choosing a motor

selecting the right motor

When you start a motion application, do you select the motor based on design criteria or habit? Do you select a servo because it is what you always use? Do you select a stepper only for simple applications?

This section will help you understand the questions you should ask to find the best motor for the application.

questions to ask

questions to ask

1.What is the load I need to move?

2.What are the speeds I need to run at?

3.Does my load vary throughout the move?

4.Are there any special functions I need such as holding torque or torque limiting?

5.What is my budget?

6.Which motor is best for my application?

1. What is the load I need to move? (torque)

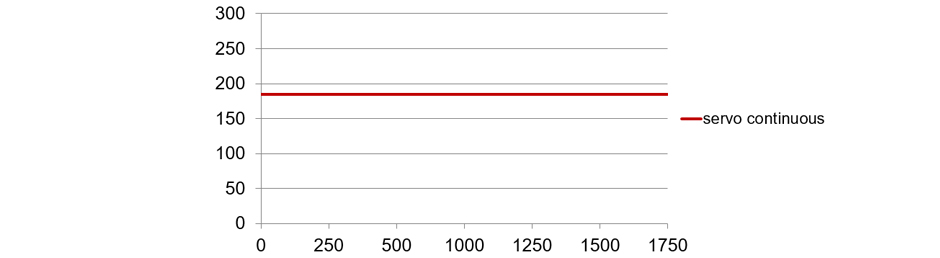

When we select a motor for an application we need to know how much torque the motor can supply. For this we use a motor torque curve. Here is a typical servo motor torque curve.

2. What are the speeds I need to run at? (Torque + Speed)

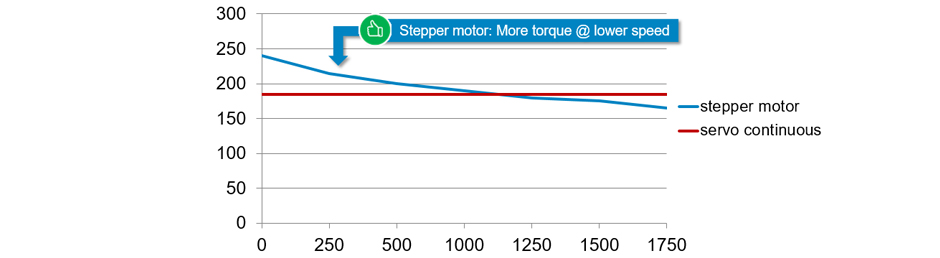

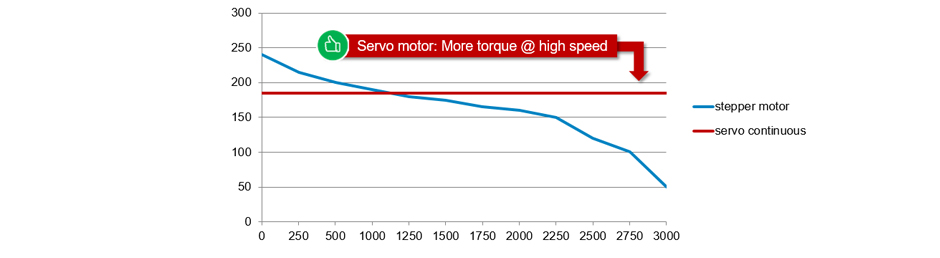

It’s often assumed servo motors outperform steppers of equivalent size. But this often not the case. Here is an equivalent sized stepper motor torque curve compared to the servo torque curve.

At high speeds the stepper motor torque approaches zero while the servo motor provides consistent torque throughout the entire speed range.

3. Does my load vary throughout the move?

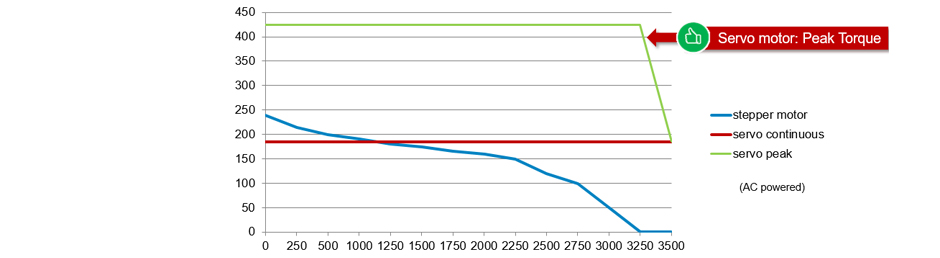

Servo motors have the additional ability to provide peak torque for brief moments to overcome variations in load and higher motor acceleration.

4. Special Functions: Holding Torque

Stepper motors can provide full torque at standstill while the windings are energized, holding a load against an external force when the rotor is not rotating - holding torque. This feature make stepper motors a good choice for cases where a load needs to be held in place.

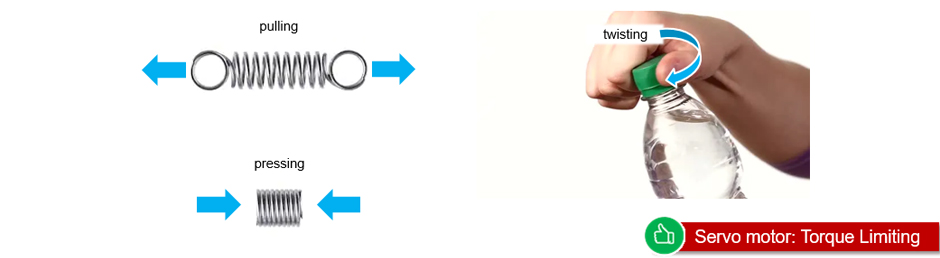

4. Special Functions: Torque Limiting

Servo motors can control motor torque through precise monitoring of the current provided to the motor, and limits it so a specific torque value cannot be exceeded – torque limiting. With the advantages of torque control, many applications that require precise force control for pressing, pulling and twisting motions can be accomplished.

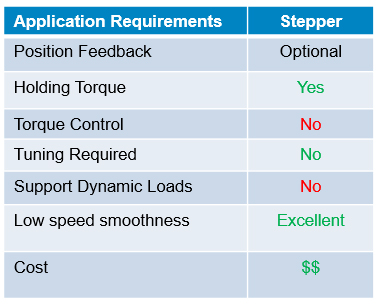

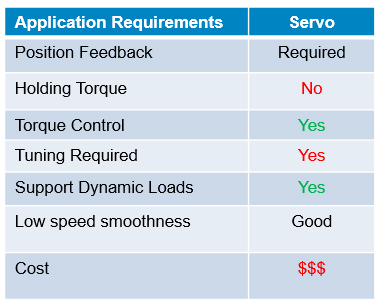

5. What is my budget: Stepper Motor Costs

Stepper motors typically don’t require feedback, use less expensive magnets, and rarely incorporate gearboxes. Because of the high pole count and their ability to generate holding torque, they consume less power at zero speed. As a result, a stepper motor is generally less expensive than a comparable servo motor.

5. What is my budget: Servo Motor Costs

Servo motors require feedback, use more expensive magnets, and often incorporate gearboxes. They also consume more power at zero speed. As a result, a servo motor is generally more expensive than a comparable stepper motor.

6. which motor is best for my application?

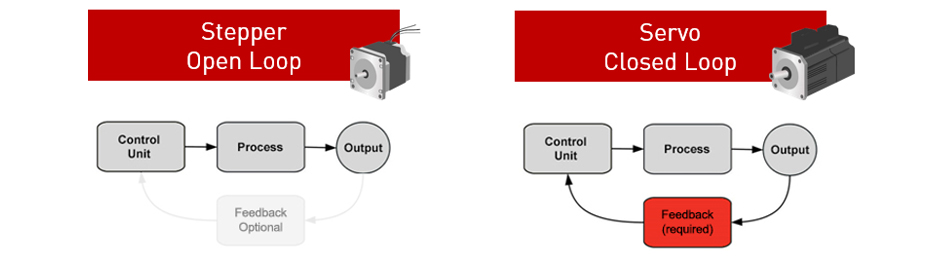

How the motors are controlled is quite different when comparing a stepper to a servo. A stepper is an open-loop system while a servo is a closed loop system. Review your application needs to determine if one control method provides features that set it apart from the other.

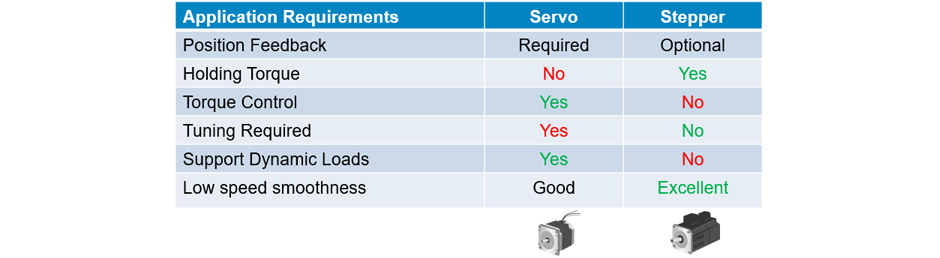

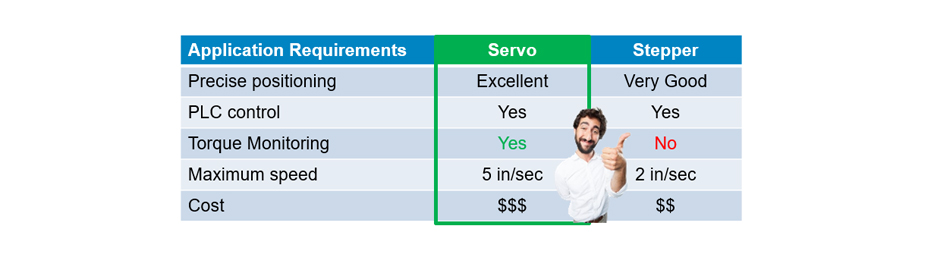

When considering application requirements, there are several parameters that need to be considered, and the chart below provides a good starting point to help guide the designer to the more appropriate technology.

when to choose a stepper solution

![]() Consider using a stepper when your application meets any of these requirements.

Consider using a stepper when your application meets any of these requirements.

![]() High torque, low speed

High torque, low speed

![]() Short, rapid, repetitive moves

Short, rapid, repetitive moves

![]() Simple control is desired

Simple control is desired

![]() Low speed, high accuracy

Low speed, high accuracy

![]() Benefits of Stepper

Benefits of Stepper

![]() Rugged construction

Rugged construction

![]() High reliability means no maintenance

High reliability means no maintenance

![]() No system tuning is required

No system tuning is required

![]() Low system cost

Low system cost

when to choose a servo solution

![]() Consider using a servo when your application meets any of these requirements.

Consider using a servo when your application meets any of these requirements.

![]() High speed is required

High speed is required

![]() Dynamic motion profiles

Dynamic motion profiles

![]() Control the applied force

Control the applied force

![]() Benefits of Servo

Benefits of Servo

![]() Torque control

Torque control

![]() Can execute complex motion commands

Can execute complex motion commands

![]() Can adjust to changes in load

Can adjust to changes in load

![]() Lower power consumption

Lower power consumption

Application examples

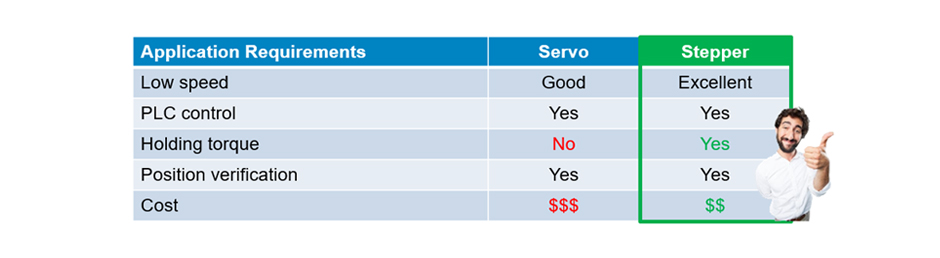

stepper application: set-up axes

Automated Roller Adjustment

Specifics: Manufacturer looking to automate roller setup.

The Goal: To reduce changeover time and increase repeatability between various production set ups.

Application Requirements:

![]() Integrate into existing PLC Control

Integrate into existing PLC Control

![]() Cycle time of under 1 minute

Cycle time of under 1 minute

![]() Make micro adjustments on demand

Make micro adjustments on demand

![]() Monitor position

Monitor position

![]() Need to hold position at rest

Need to hold position at rest

The Solution

The stepper’s better low speed smoothness and

holding torque at rest make the stepper the

better choice.

servo application: dynamic torque control

Bottle Capper

Specifics: OEM builder of filling and bottling lines needs a linear and rotary actuator as part of an update to a capping operation.

The Goal: To place the cap accurately and report any missing or misapplied caps.

Application Requirements:

![]() Integrate into existing PLC Control

Integrate into existing PLC Control

![]() Very high throughput

Very high throughput

![]() Cap on-torque limit

Cap on-torque limit

![]() Multiple products

Multiple products

The Solution

The servo’s closed loop control allows for better

monitoring of motor position and current control.

Torque limiting of the servo gives the system the

ability to precisely apply the caps to correct cap

on torque.

AMCI Integrated Motion Solutions

Motor + Drive + Controllers

AMCI's integrated motor product families provide a complete solution by incorporating the motor, drive, & controller into a single package that offers the simplest installation possible.

Key Terminology

Closed Loop: A system where the output is measured and compared to the input. The output is then adjusted to reach the desired condition. In a motion system a velocity or position(or both) sensor is used to generate the correction signals by comparison to desired parameters

Holding Torque: The maximum external force or torque that can be applied to a stopped, energized motor without causing the motor to rotate continuously.

Microstepping: A control technique that proportions the current in a step motor’s wind to provide intermediate positions between poles.

Open Loop: Refers to a motion system where no external sensors are used to provide velocity or position correction signals.

Rated Torque: The torque producing capacity of a motor at a given speed. This is the maximum torque the motor can deliver to a load and is usually specified with a toque/speed curve.

Servo: A system consisting of several devices which continuously monitor actual information, compares those values to a desired outcome and makes the necessary corrections to minimize the difference.

Step Angle: The angle the shaft rotates upon receipt of a single step command. For a standard two-phase stepper motor the step angle is 1.8 degrees (200 steps/turn) when controlled with a full step drive.