ANG1(X) AnyNET-I/O Integrated Stepper Motor Controller + Drive Networked I/O

Description

ANG1(X) AnyNET-I/O Integrated Stepper Motor Controller + Drive Networked I/O

AMCI’s ANG1(X) Integrated Stepper Controller/Drive product is a ground breaking approach to PLC-based motion control systems.

Traditional motion controllers are difficult to integrate with PLC-based automation systems. There are so many manufacturers, so many different choices, and each solution contains proprietary features that complicate installation, programming, and compatibility. You’re also faced with mechanical challenges because these motion controllers often use non-standard mounting hardware. And their configuration involves learning another software program and/or language foreign to your controls environment.

AMCI’s ANG1(X) eliminates these headaches with a revolutionary design that leverages modern networks to deliver unmatched value to automation users, no matter what PLC or PAC they’re using.

Expandable Motion Control: 1 - 6 Axes

The ANG1(X) integrates a stepper controller and driver into one, compact package that communicates with the host controller (your PLC or PAC) over the network. All programming is performed by the same software used to configure your PLC, plus it mounts on a standard EN 05 022 – 35 X 7.5 DIN rail to simplify installation and lower costs.

Available Versions

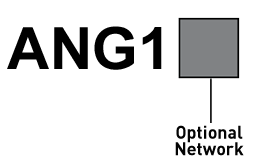

ANG1(X): X = network interface

ANG1E: (EtherNet IP & Modbus TCP/IP)

ANG1P: (Profibus)

Expansion module

ANG1: no network interface

Consult the factory for pricing & availability

Contact SalesANG1(X) Features

- Integrated Stepper controller AND driver

- Built-in network interface for a variety of networks

- Works with all PLCs and PACs that EtherNet/IP, Modbus-TCP, or Profibus!

- 1 to 6 axis of motion control - buy what you need, expand later!

- Hybrid control: Servo performance using Stepper hardware

- Encoder feedback - operate Open or Closed Loop

- Programming is easy, no additional software required

- DIN rail mounting for simple, standard installation

Stepper Control with Servo Performance

AMCI’s ANG1(X) introduces Hybrid Control. AMCI's Engineering Group combined the strengths of Stepper and Servo technology into one motion control product. We’ve eliminated compromise.

Traditionally, stepper control was the preferred technology for low speed, high torque applications involving repetitive motion. The affordability of stepper control automation made it an attractive option, especially since installing and programming a complete system was straightforward.

Alternatively, some applications require dynamic performance related to shifts in load. This type of automation was best suited to Servo systems that use encoder position feedback to optimize acceleration, speed, and torque throughout the motion control. Servo systems are powerful, but expensive. Plus, their sophistication comes at a cost of complex programming and PID tuning.

The ANG1(X) is a “best of breed” product that delivers exceptional performance across a range of applications. Like a stepper, AMCI’s ANG1(X) delivers excellent low speed, high torque motion control at an affordable price. Like a servo, AMCI’s ANG1 can be equipped with encoder feedback to deliver closed loop performance that responds dynamically to changes in load.

Finally a high performance, low cost, and easy to program integrated motion controller that consolidates hardware (controller & drive) while working with a variety of PLCs and PACS.

Hybrid Control

PLC-Based Specialty I/O Solutions

AMCI’s AnyNET-I/O family is a distributed I/O system that combines hard to find specialty functions with a network interface, simplifying installation and cutting costs. The product family allows users to “mix & match” functions, including stepper motion

control and a variety of sensor interfaces, in a single solution.

AnyNET-I/O is compatible with any networked PLC/PAC and easily programs through the host PLC’s software. Its innovative product design simplifies installation, optimizes network performance, and ensures system integrity.

Multi-axis motion control: (1) ANG1(X) + (5) ANG1 shown below

The ANG1(X) easily expands from 1-to-6 axis of motion control by stacking additional controller drives onto the “master”, and it only requires a single network connection for all communication. This innovative product design simplifies installation, optimizes network performance, and ensures system integrity. Please see the diagram below for details.

Compatible Networks

AnyNET-I/O is compatible with any networked PLC

The Best PLC Integration Available

AMCI products are uniquely designed to provide the best PLC integration available. Unlike other products that require a separate software package for configuration or operation, AMCI's PLC-based products are programmed using your PLC's software - nothing new to buy or learn!

Our expertise with the leading PLC manufacturers (e.g. Allen-Bradley Schneider, GE, etc) is unmatched when it comes to high performance Specialty I/O, Position Sensing, and Motion Control technology.

Program Using Your Existing Software

AMCI's products program using your PLC's native software - nothing new to learn or buy!

Specifications

Electrical Specifications

| AMCI Module | ANG1(X) |

|---|---|

| Network Availability | ANG1E (EtherNet IP & Modbus TCP/IP) ANG1P (Profibus) |

| Amplifier Type | Bipolar with two MOSFET H-bridges; RMS current control, 20 kHz PWM |

| Supply voltage | 24 to 48 Vdc, surge to 60Vdc |

| Auxilary Input specs. | -Differential. DC Inputs accept 3.5 to 27Vdc without the need for an external current limiting resistor. 1500 Vac/dc opto-isolated. Can be wired as single ended inputs. -Encoder Inputs are designed for 5Vdc differential and require external current limiting resistor for 12 to 24Vdc operation The three differential inputs can be configured to be used as Home, Emergency Stop, Over Travel Limit Switches, Start Index Move, Stop Jog or Registration input, Capture Encoder Position, or as a General Purpose Input. |

| Fault output | open collector/emitter 30Vdc max & 20 mA max One output is configurable as a Fault Output or as a General Purpose Output |

Electrical Specifications

ANG1P (Profibus)

-Encoder Inputs are designed for 5Vdc differential and require external current limiting resistor for 12 to 24Vdc operation

The three differential inputs can be configured to be used as Home, Emergency Stop, Over Travel Limit Switches, Start Index Move, Stop Jog or Registration input, Capture Encoder Position, or as a General Purpose Input.

One output is configurable as a Fault Output or as a General Purpose Output

Operational Specifications

| AMCI Module | ANG1(X) |

|---|---|

| Current rating | 4.0 Arms (average current)/5.7A peak (peak current) NOTE: There are 2 ways to express the magnitude of current in microstepping stepper motor drivers, RMS and Peak. 1 amp RMS = 1.414 amp Peak. AMCI's ANG1 stepper motor controller/driver is rated for 4.0 amp RMS or 5.7 amp Peak. |

| Available commands | -Absolute Move -Relative Move -Hold Move -Resume Move -Immediate Stop -Homing -Jogging -Registration Move -Indexed Move -Blend Moves -Reset Errors -Preset Position -reset Encoder Position -Electronic Gearing (only when the ANG1 is configured to use a quadrature encoder) |

| Motor Step per Revolution Resolution | Programmable to any value between 200 and 32,767 steps per revolution. The ANG1 uses variable step size motion for extreme smoothness regardless of programmed resolution. |

| Maximum velocity | motor/load dependent |

| Output current | 0.1A - 4.0A rms selectable in 0.1 amp increments, programmable over EtherNet/IP & Modbus TCP |

| Maximum operating temp. | (-20° to 50°C) ambient temperature |

| Idle current | Programmable from 0% to 100% programmed motor current in 1% increments. Motor current is reduced to selected level if there is no motion for 1.5 seconds. Current is restored to full value when motion is started. |

| Motor connections | Eight lead series or parallel, six lead series or center tapped, or four lead motors using a four pin motor connector. |

| Included connectors | MS-2x11 - I/O connector MS-4M - motor connector |

| Mounting | AnyNET-I/O modules can be mounted on the following DIN Rail types -EN 05 022 - 35 x 7.5 (35 x 7.5 mm) If you are only installing one ANG1E module instead of an interconnected stack, then you can also use the following DIN rail. -EN 05 022 - 35 x 15 (35 x 15 mm) |

Operational Specifications

(peak current)

NOTE: There are 2 ways to express the magnitude of current in microstepping stepper motor drivers, RMS and Peak.

1 amp RMS = 1.414 amp Peak.

AMCI's ANG1 stepper motor controller/driver is rated for 4.0 amp RMS or 5.7 amp Peak.

-Relative Move

-Hold Move

-Resume Move

-Immediate Stop

-Homing

-Jogging

-Registration Move

-Indexed Move

-Blend Moves

-Reset Errors

-Preset Position

-reset Encoder Position

-Electronic Gearing (only when the ANG1 is configured to use a quadrature encoder)

MS-4M - motor connector

-EN 05 022 - 35 x 7.5 (35 x 7.5 mm)

If you are only installing one ANG1E module instead of an interconnected stack, then you can also use the following DIN rail.

-EN 05 022 - 35 x 15 (35 x 15 mm)

Hardware protection

| AMCI Module | ANG1(X) |

|---|---|

| Hardware protection | -Short circuit protection - phase to phase and phase to ground. -Overtemperature circuitry. |

Hardware protection

-Overtemperature circuitry.

Video

AMCI ANG1(X) Stepper Controller/Drive with Network Interface

AMCI's ANG1(X) integrates drive and controller technology, simplifying installation and cutting costs. Move commands are easily programmed using the PLC's native software, and cabling is drastically reduced with the ability to expand up to 6 axes of motion over a single network connection.

Duration 00:45

Accessories

AMCI makes buying PLC-based automation easy...our sales group will help you:

- Select the right product for your application

- Pay by credit card using your Visa, Mastercard, Discover, or American Express

- Coordinate alternative payment methods (P.O., wire transfers, etc.)

- Locate a distributor convenient to your region of the country

Contact AMCI Sales today:

860-585-1254

Ordering Information

AMCI's sales team takes the hassle out of placing your order. We'll advise on product selection, alternatives, lead times, and present you with point of purchase options. Call (860) 585-1254 or email AMCI sales today!

Create Your Part Number

Generate your ANG1(X) AnyNET-I/O Integrated Stepper Motor Controller + Drive Networked I/O part number by using this helpful ordering guide. Starting from left to right, use the following diagram and table to choose the desired options.

Part Number Guide

| Part Number Character | ANG1(X) AnyNET-I/O Integrated Stepper Motor Controller + Drive Networked I/O |

|---|---|

| Optional Network: | E = EtherNet IP & Modbus TCP/IP P = Profibus (leave blank for expansion module) |

Part Number Guide

P = Profibus

(leave blank for expansion module)

Resources

ANG1(E) Product Sheet

ANG1(E) Integrated Stepper Controller & Drive: Built-in ethernet interface, expandable 1-6 ...

PDF DownloadAnyNET-I/O Brochure

AnyNET-I/O Networked Specialty I/O - a distributed I/O system that combines hard to find specia...

PDF DownloadWebinar

Programming AMCI EtherNet/IP Motion Products with RSLogix/Studio 5000: This 30 minute webinar a...

Watch Now