DC25 Absolute Analog Rotary Shaft Encoder

Description

AMCI DC25 Absolute Analog Single-turn Rotary Shaft Encoder

Designed as a replacement for potentiometers, this absolute analog rotary shaft encoder is an industry leading member of the DC25 DuraCoder family.

Popular applications include closed loop process control and angular measurement of valves, dampers and sorters.

Available with analog voltage or analog current output, the analog DuraCoder has an output format for any application requiring an absolute analog rotary shaft encoder position sensor.

The analog output DC25 DuraCoder can be selected to produce the full output signal over 360, 180, 90, or 45 degrees. Available analog voltage outputs include 0-5Vdc, 0-10Vdc, or +/-10Vdc. The analog current output versions are 4 to 20mA or 0 to 20mA. Package styles include flange or servo with side or end connector.

Available Versions (x = any selection)

DC25x-BxVxxx: Absolute, voltage output analog DuraCoder

DC25x-BxCxxx: Absolute, current output analog Duracoder

Stainless Steel Option Available

Consult the factory for pricing & availability

Contact SalesHeavy-Duty Reliability

AMCI's DuraCoder rotary shaft encoders are resolver-based, providing the heaviest duty 2.5" rotary shaft encoder available, anywhere. Several features set this family of rotary encoders apart from the competition; namely, its cost saving durability, field programmability, and wide range of applications.

- Cost-saving durability

- Resolver-based reliability

- Field programmable output resolution

- Wide range of applications

- More...

AMCI resolver-based rotary shaft encoders have earned a "bulletproof" reputation among established machine builders and successful system integrators.

The AMCI DuraCoder product line boasts up to an IP67 rating. Solid shaft and hub shaft versions are available, and both types incorporate an oversized double row bearing that supports shaft loads up to 100 lbs. radial / 50 lbs. axial.

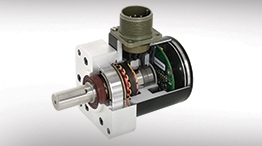

Inside AMCI's Rotary Encoders

Specifications

Mechanical Specifications

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Package style: | 2.5" diameter housing available with flange or servo mounting |

| Housing: | Powder coated aluminum or stainless steel housing |

| Shaft sizes: | Solid shaft diameter 1/4" , 3/8", 5/8”, or 10 mm diameter stainless steel Hub shaft inner diameter 1/2” standard inner diameter stainless steel shaft 3/8", 1/2", 10mm, and 12mm bore reducers |

| Shaft loading: | Solid shaft: 1/4", 3/8", and 10mm shafts: 40 lbs. radial/20 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. 5/8" shaft: 100 lbs. radial/50 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts: 40 lbs. radial/20 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. |

| Starting Torque: | Solid shaft: 1/4”, 3/8”, & 10mm shafts = 2.0 oz-in max @25° C 5/8” shaft = 6.0 oz-in max @25° C Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts = 6.0 oz-in max @25° C |

| Moment of inertia: | Solid shaft: 1/4", 3/8", & 10 mm shafts = 6.00 x 10-4 oz-in-sec2 5/8" shaft = 8.50 x 10-4 oz-in-sec2 Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts = 8.50 x 10-4 oz-in-sec2 |

| Connector location: | end or side |

Mechanical Specifications

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Package style: | 2.5" diameter housing available with flange or servo mounting |

| Housing: | Powder coated aluminum or stainless steel housing |

| Shaft sizes: | Solid shaft diameter 1/4" , 3/8", 5/8”, or 10 mm diameter stainless steel Hub shaft inner diameter 1/2” standard inner diameter stainless steel shaft 3/8", 1/2", 10mm, and 12mm bore reducers |

| Shaft loading: | Solid shaft: 1/4", 3/8", and 10mm shafts: 40 lbs. radial/20 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. 5/8" shaft: 100 lbs. radial/50 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts: 40 lbs. radial/20 lbs. axial maximum shaft loading. Bearing life rated at 2X10^9 revolutions minimum at maximum shaft load. |

| Starting Torque: | Solid shaft: 1/4”, 3/8”, & 10mm shafts = 2.0 oz-in max @25° C 5/8” shaft = 6.0 oz-in max @25° C Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts = 6.0 oz-in max @25° C |

| Moment of inertia: | Solid shaft: 1/4", 3/8", & 10 mm shafts = 6.00 x 10-4 oz-in-sec2 5/8" shaft = 8.50 x 10-4 oz-in-sec2 Hub shaft: 3/8", 1/2", 10mm, and 12mm shafts = 8.50 x 10-4 oz-in-sec2 |

| Connector location: | end or side |

Mating Connector: (sold seperately)

| AMCI Part Number | Military Equivalent | |

| Straight | MSD-10 | MS3106A18-1S |

| consult factory for integral cable option | ||

Mating Connector: (sold seperately)

| AMCI Part Number | Military Equivalent | |

| Straight | MSD-10 | MS3106A18-1S |

| consult factory for integral cable option | ||

Connector Pinout: (Military Equivalent Part # MS3102E18-1P)

| Pin | Function |

| A | No connection |

| B | No connection |

| C | +DC input |

| D | DIR control |

| E | DC return |

| F | Analog output |

| G | No connection |

| H | Case ground |

| I | DC return |

| J | Preset input |

Connector Pinout: (Military Equivalent Part # MS3102E18-1P)

| Pin | Function |

| A | No connection |

| B | No connection |

| C | +DC input |

| D | DIR control |

| E | DC return |

| F | Analog output |

| G | No connection |

| H | Case ground |

| I | DC return |

| J | Preset input |

Electrical Specifications

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Output precision: | 12 bit analog voltage or current |

| Power up setting time: | 20 mSec. max. |

| Voltage configuration: | 0 to 5 Vdc, 0 to 10 Vdc, ±10 Vdc |

| Voltage load capacity: | 2K ohm min. |

| Current configuration: | 4-20 mA, 0-20 mA |

| Current load capacity: | Vin <= 15Vdc: 420 ohm max Vin = 24Vdc: 950 ohm max |

| Power requirements: | 4.75 to 26.4 Vdc 1.8W max. |

Electrical Specifications

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Output precision: | 12 bit analog voltage or current |

| Power up setting time: | 20 mSec. max. |

| Voltage configuration: | 0 to 5 Vdc, 0 to 10 Vdc, ±10 Vdc |

| Voltage load capacity: | 2K ohm min. |

| Current configuration: | 4-20 mA, 0-20 mA |

| Current load capacity: | Vin <= 15Vdc: 420 ohm max Vin = 24Vdc: 950 ohm max |

| Power requirements: | 4.75 to 26.4 Vdc 1.8W max. |

ENVIRONMENTAL SPECIFICATIONS

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Enclosure: | IP67 (valid only with working shaft seal) |

| Shock: | 50 G's for 11 mSec |

| Vibration: | 20 g, 5 to 2,000 Hz |

| Operating temperature: | -40° C to 85° C standard |

ENVIRONMENTAL SPECIFICATIONS

| DC25 Absolute Analog Single-turn Rotary Shaft Encoder | |

|---|---|

| Enclosure: | IP67 (valid only with working shaft seal) |

| Shock: | 50 G's for 11 mSec |

| Vibration: | 20 g, 5 to 2,000 Hz |

| Operating temperature: | -40° C to 85° C standard |

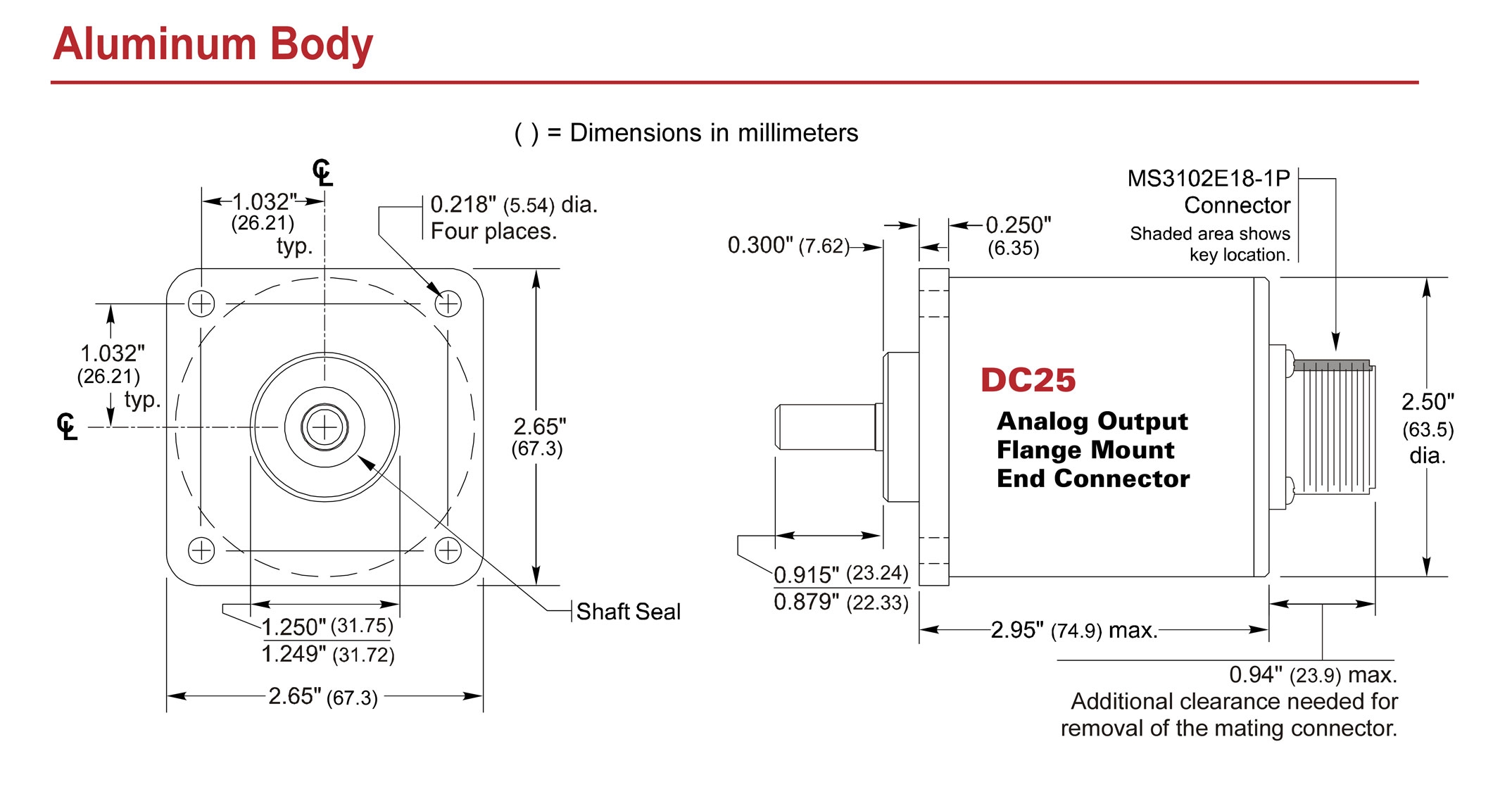

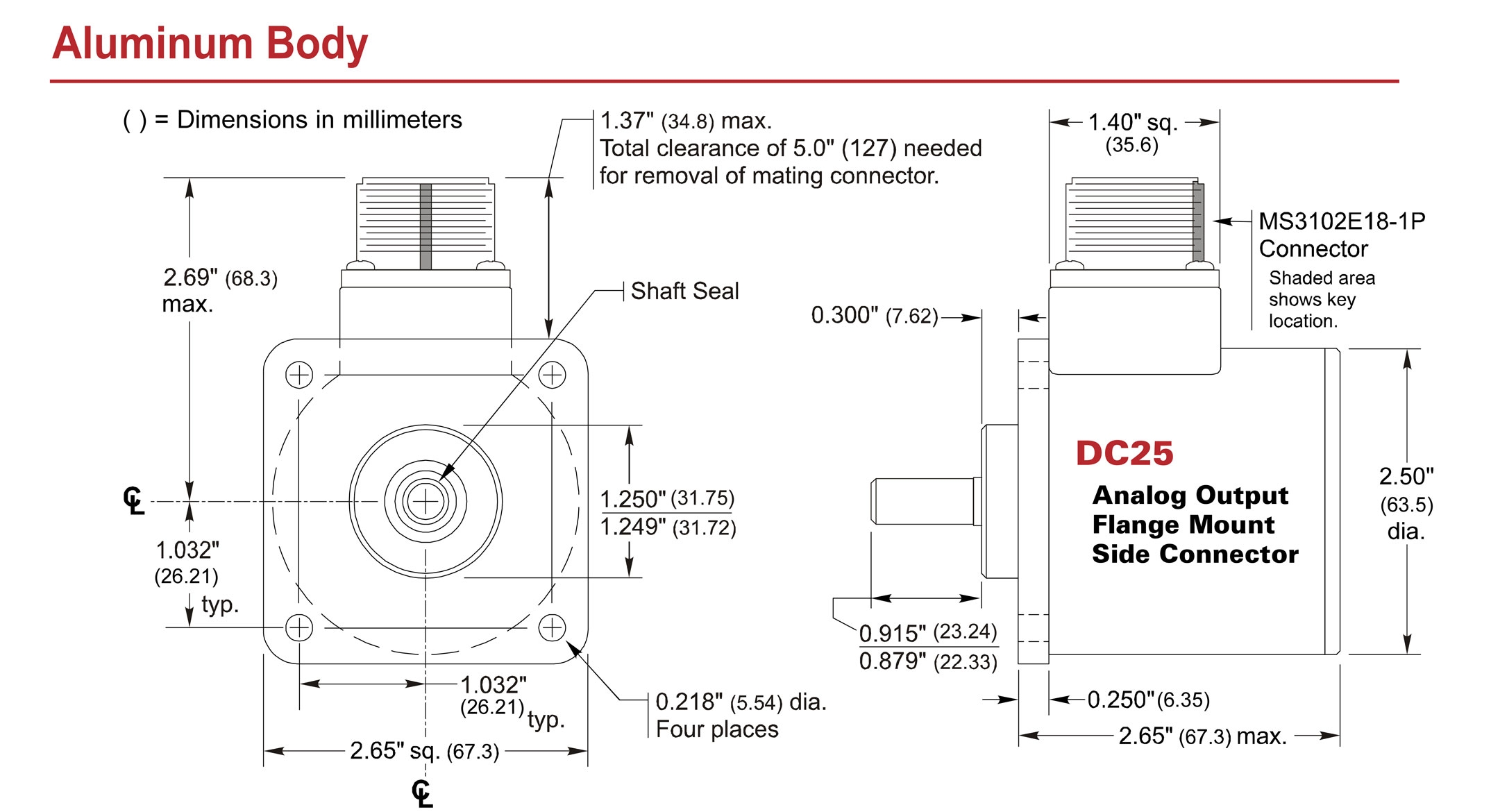

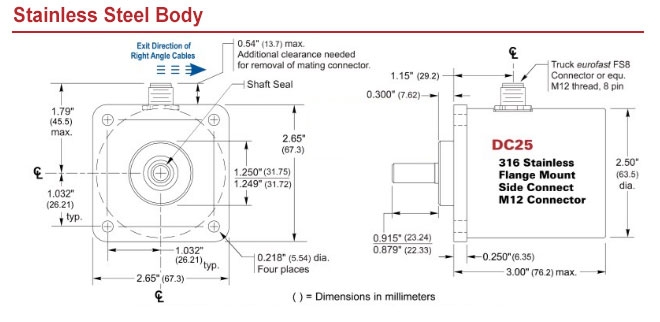

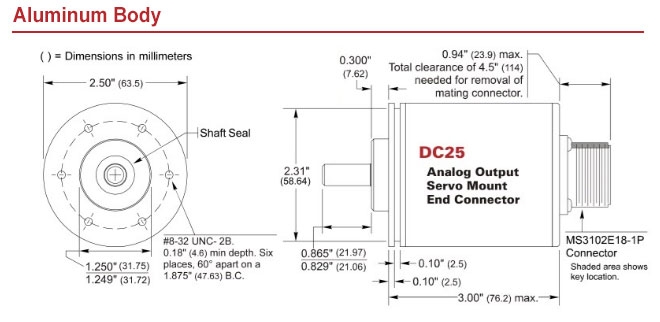

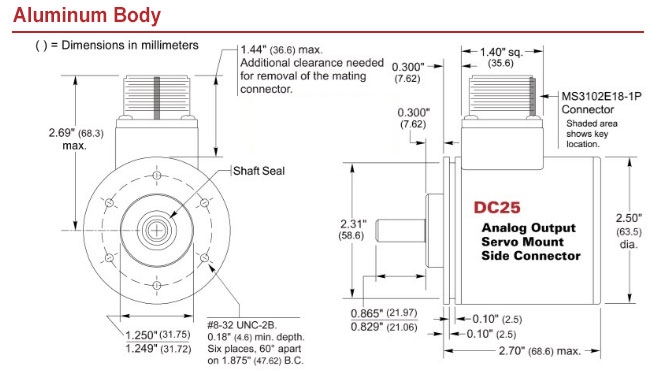

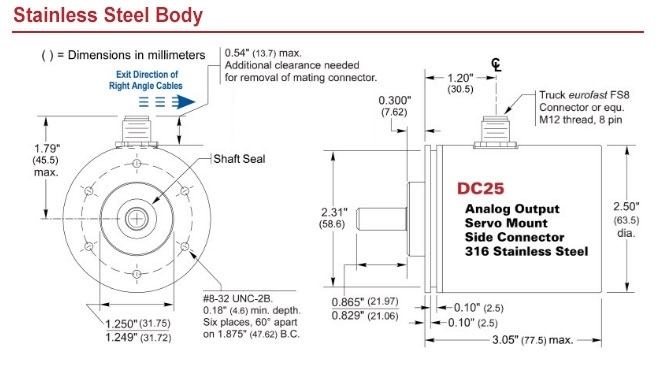

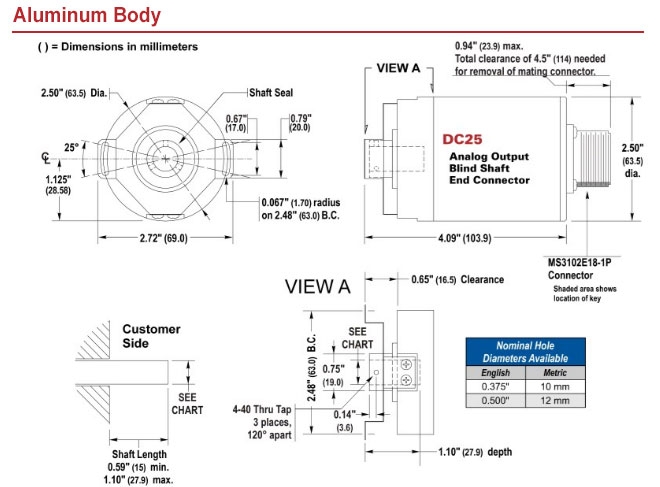

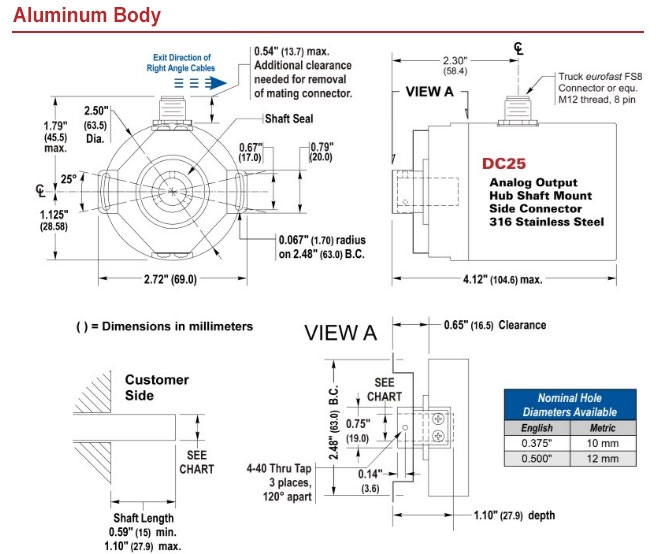

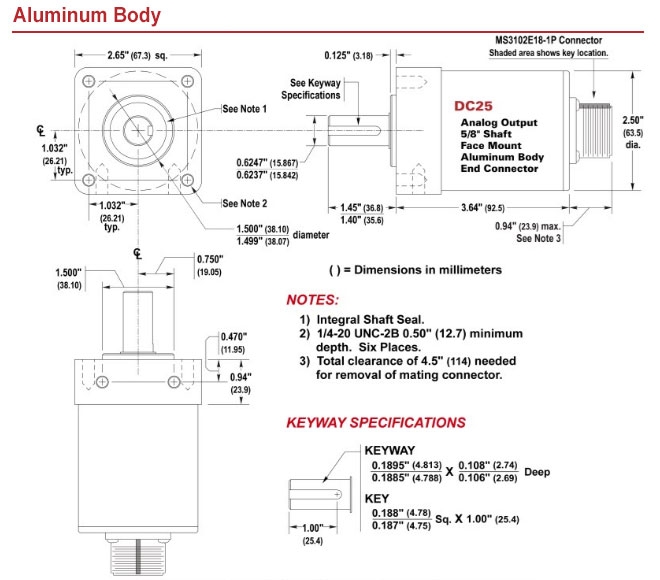

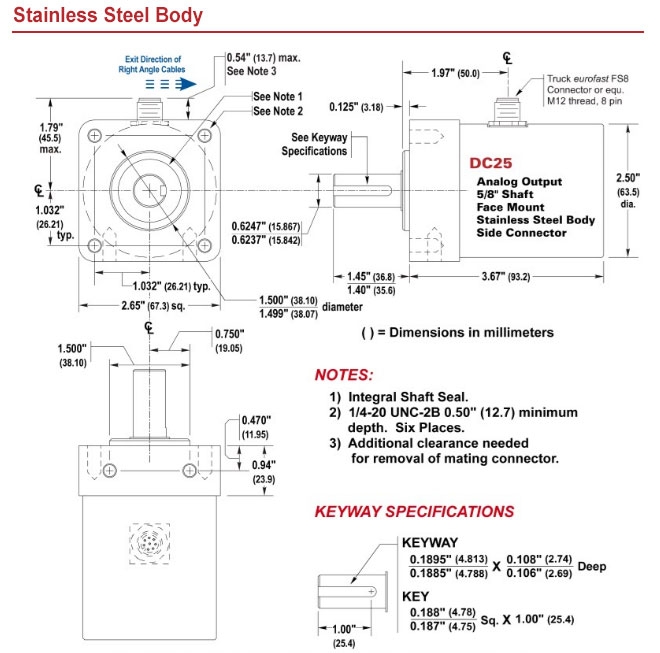

Technical Drawings

DC25 Absolute Analog: Flange Mount, Aluminum, End connector

DC25 Absolute Analog: Flange Mount, Aluminum, Side Connector

DC25 Absolute Analog: Flange Mount, Stainless, Side Connector

DC25 Absolute Servo Mount, Aluminum, End Connector

DC25 Absolute Servo Mount, Aluminum, Side Connector

DC25 Absolute Servo Mount, Stainless, Side Connector

DC25 Absolute Hub Shaft, Aluminum, End Connector

DC25 Absolute Hub Shaft, Stainless, Side Connector

DC25 Absolute 5/8" Shaft, Face Mount, Aluminum, End Connector

DC25 Absolute 5/8" Shaft, Face Mount, Stainless, Side Connector

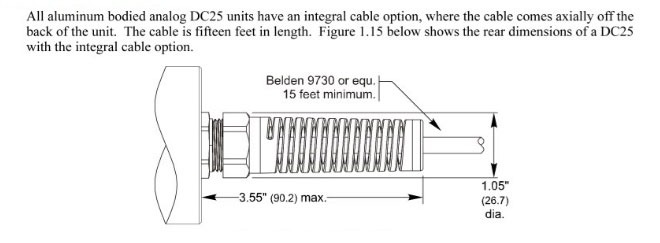

Integral Cable Option

AMCI makes buying PLC-based automation easy...our sales group will help you:

- Select the right product for your application

- Pay by credit card using your Visa, Mastercard, Discover, or American Express

- Coordinate alternative payment methods (P.O., wire transfers, etc.)

- Locate a distributor convenient to your region of the country

Contact AMCI Sales today:

860-585-1254

Ordering Information

AMCI's sales team takes the hassle out of placing your order. We'll advise on product selection, alternatives, lead times, and present you with point of purchase options. Call (860) 585-1254 or email AMCI sales today!

PART NUMBER BUILDER

Create your part number

Generate your DC25 part number by using the interactive tool below. Starting from left to right, use choose your selections from the drop down options while referencing the table below.

- Customers concerned with availability should request lead times on units with both the side and end connector location options

| Part Number Character | Absolute Analog Single-turn DuraCoder Selections | Most Popular Selections |

|---|---|---|

| Mounting style: | F = Square flange S = 2.5" diameter servo mount (unavailable w/ the 5/8" shaft option) H = Hub shaft | F (Square flange) |

| Shaft Seal Type & Housing Material: | A = Nitrile seal, stainless steel housing B = Nitrile seal, aluminum housing C = Viton seal, stainless steel housing V = Viton seal, aluminum housing | B (Nitrile seal) |

| Shaft Diamter: (must choose either solid or hub shaft) | Solid shaft option 1 = 3/8" diameter 0.875” length, No Flat 2 = 10mm diameter 0.875” length, No Flat 3 = 1/4" diameter 0.875” length, No Flat 5 = 5/8" diameter 1.30” length, w/ Keyway --- Hub shaft option 1 = 3/8" inner diameter 1.1” max. depth 2 = 10mm inner diameter 1.1” max. depth 4 = 1/2" inner diameter 1.1” max. depth 6 = 12mm inner diameter 1.1” max. depth | 1 (3/8" shaft) --or-- 4 (1/2" inner diameter) |

| DuraCoder Type: | V = Analog voltage C = Analog current | V or C |

| Output Scaling: | If DuraCoder Type = V 1 = 0 to 5Vdc 2 = 0 to 10Vdc 4 = -10V to +10Vdc --- If DuraCoder Type = C 1 = 4 to 20mA 2 = 0 to 20mA | 2 (0 to 10 Vdc) --or-- 1 (4 to 20 mA) |

| Output Configuration: | K = 360° output period L = 180° output period M = 90° output period N = 45° output period | K (360° output period) |

| Connector Location: | S = Side E = End FL = 15 ft integral cable (MSD-10 mating connector sold separately) | S (Side connector) |

| Cable: | CDCAV-X (where X is the length in feet) cable (sold separately) | |

| Part Number Character | Absolute Analog Single-turn DuraCoder Selections | Most Popular Selections |

|---|---|---|

| Mounting style: | F = Square flange S = 2.5" diameter servo mount (unavailable w/ the 5/8" shaft option) H = Hub shaft | F (Square flange) |

| Shaft Seal Type & Housing Material: | A = Nitrile seal, stainless steel housing B = Nitrile seal, aluminum housing C = Viton seal, stainless steel housing V = Viton seal, aluminum housing | B (Nitrile seal) |

| Shaft Diamter: (must choose either solid or hub shaft) | Solid shaft option 1 = 3/8" diameter 0.875” length, No Flat 2 = 10mm diameter 0.875” length, No Flat 3 = 1/4" diameter 0.875” length, No Flat 5 = 5/8" diameter 1.30” length, w/ Keyway --- Hub shaft option 1 = 3/8" inner diameter 1.1” max. depth 2 = 10mm inner diameter 1.1” max. depth 4 = 1/2" inner diameter 1.1” max. depth 6 = 12mm inner diameter 1.1” max. depth | 1 (3/8" shaft) --or-- 4 (1/2" inner diameter) |

| DuraCoder Type: | V = Analog voltage C = Analog current | V or C |

| Output Scaling: | If DuraCoder Type = V 1 = 0 to 5Vdc 2 = 0 to 10Vdc 4 = -10V to +10Vdc --- If DuraCoder Type = C 1 = 4 to 20mA 2 = 0 to 20mA | 2 (0 to 10 Vdc) --or-- 1 (4 to 20 mA) |

| Output Configuration: | K = 360° output period L = 180° output period M = 90° output period N = 45° output period | K (360° output period) |

| Connector Location: | S = Side E = End FL = 15 ft integral cable (MSD-10 mating connector sold separately) | S (Side connector) |

| Cable: | CDCAV-X (where X is the length in feet) cable (sold separately) | |

Resources

Encoders Brochure

Originally designed for mill-duty applications and earth mining equipment, AMCI’s resolver-base...

PDF DownloadResolver-Based?

Resolver-based Rotary Shaft Encoders provide the heaviest duty 2.5" rotary shaft encoder availa...

Read the TutorialRail Track Grinders

The challenge was unique. Unlike most industrial applications, railway track grinders operate a...

Read Case Study